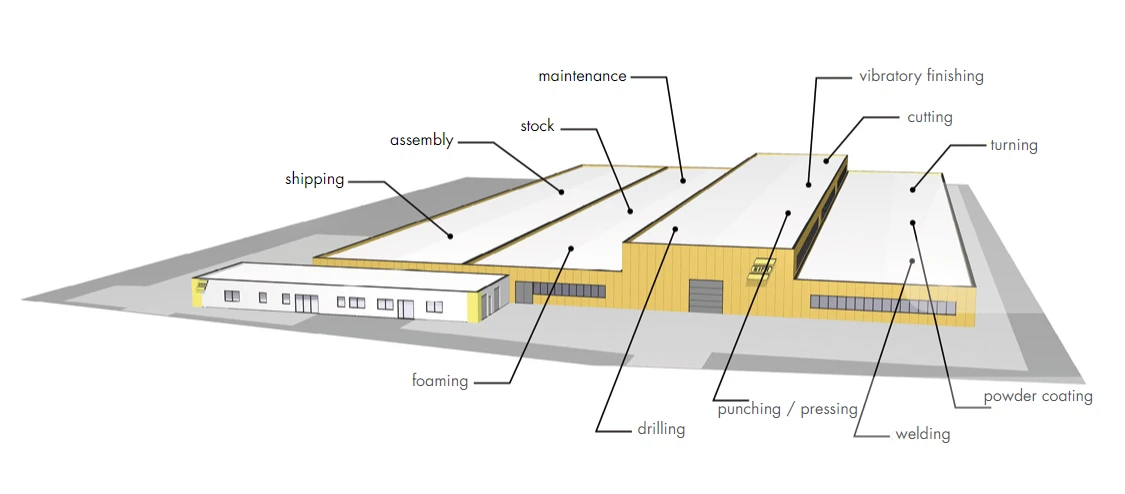

Services

In addition to the production of our standard products, we are able to respond to your wishes in a very short time thanks to our large production width.

Our machine and plant park gives us the flexibility to also implement projects for sectors outside the furniture industry.

Below you you get get an overview of our production options, from metal processing, to assembly manufacturing and polyurethane foam processing, to customer-specific packaging of the finished product.

If you have any questions, or if you are interested, please write to info@sifa.de and arrange a visit.

We look forward to hearing from you!

PU-moulding

On 3 carousels we manufacture integral foam parts with two foaming systems for different applications, both using synthetic resin and aluminium moulds. In addition, we can produce small series on a stationary place. Standard colour of our foam system is black, other colours on request.

powder coating

We have a continuous system with which we powder-coat our metal parts. In the car wash iron phosphating agent is applied for pre-treatment. Large series are powder coated in the automatic painting booth, special colours or special series can be processed in the manual painting booth.

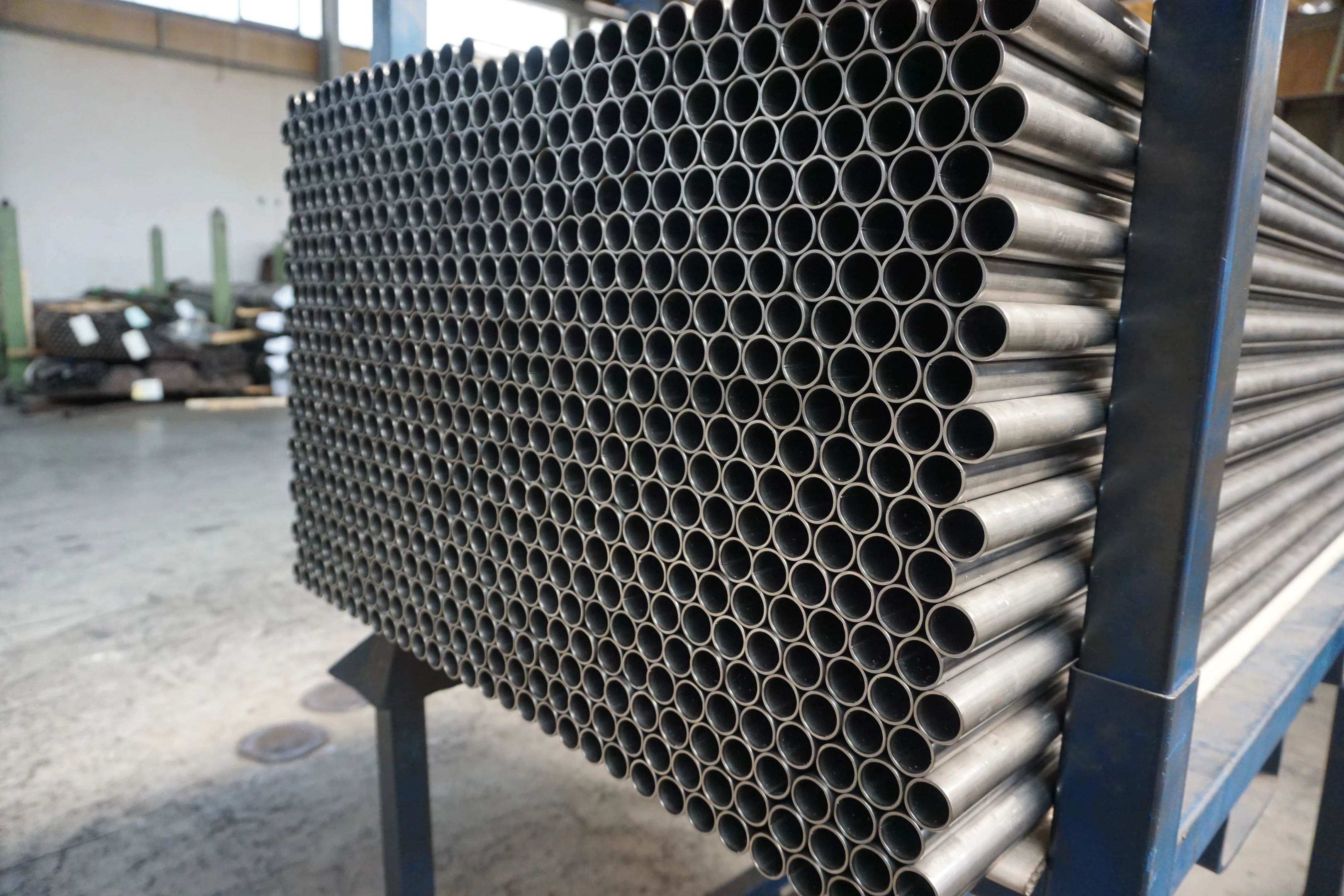

Cutting

With 2 fully automatic saws we are able to cut large series of bar stock up to a maximum diameter of 100 mm. The blanks fall burr-free from the machine by means of a connected brush deburring unit. For small series we have a circular saw and a band saw available, on both angle cuts are possible.

welding

- 6 hand welding places

- 20 welding machines for various round and longitudinal welding

- 1 electric resistance welding machine

- 1 stud welder

Punching / pressing

Our machine park with various eccentric and hydraulic presses allows us to punch both from the coil and to do smaller bending and squeezing jobs.

Press force of mechanical presses = 25-100 tons

Press force of hydraulic presses = 25-250 tons